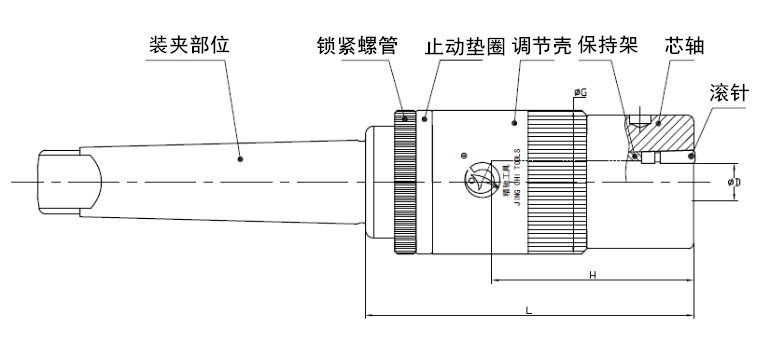

Roller Burnishing Tool Introduction

Roller burnishing tool is able to use plastic deformation of metal to roll out part surface roughness under room temperature in order to change surface structure, mechanical properties, shape and size. No matter what kind of metal processing cutter is used, there are small uneven marks on the part surface to form a peak valley phenomenon. Rolling cutter uses the principle of mechanical extrusion and it is a plastic processing method to achieve a smooth surface like mirror without mechanical cutting.

It is a pressure processing method and uses cold plastic characteristics of metal under room temperature to impose certain pressure on part surface by means of rolling cutter. Part surface metal will have plastic flow to fill in the remaining concave trough, so that part surface roughness will be reduced. As surface metal produces plastic deformation, surface structure will be hardened with fine grain to form dense fiber and residual stress layer, so that hardness and strength can be increased to improve wear resistance, corrosion resistance and matching property of the surface. As rolling is a plastic processing method without cutting, it can achieve smooth processing and strength, which can be done by grinding or turning.

Product Data

| Model |

Regulating component, Diameter and adjustment range

|

Effective Length | Shank /L | |||

| ΦD | ΦG | a | H | 直柄 | 錐柄 | L |

| Φ6-Φ10 | WA1/50 |

+0.05

-0.25

|

90 |

Φ12*40

Φ16*40

Φ20*50

|

MT2

MT3

MT4

|

120 |

| Φ11-Φ19 | WA2/55 | 125 | ||||

| Φ20-Φ28 | WA3/65 | 130 | ||||

| Φ29-Φ50 | _ | 30-50 | 160 | |||

Product Display